Die Micarna-Gruppe – Teil der Migros Industrie

Willkommen bei der Micarna-Gruppe

Die Micarna-Gruppe ist seit mehr als einem halben Jahrhundert die führende Fleisch-, Geflügel-, Ei- und Seafood-Produzentin der Schweiz und leistet als Unternehmen der Migros Industrie einen wesentlichen Beitrag zum Unternehmenserfolg der Migros. Mit über 4’500 Produkten für spezifische Kundengruppen ist die Micarna-Gruppe absatztechnisch die grösste Fleischproduzentin der Schweiz.

Die Micarna-Gruppe mit Hauptsitz in Courtepin (FR) ist ein Zusammenschluss der Micarna SA, der Lüchinger + Schmid AG, der Mérat AG und der Favorit Geflügel AG. Auch die national bekannten Marken «Schär Fleischspezialitäten», «Maurer Speck», «Fleury Viande» und «Natura» gehören zur Micarna-Gruppe.

Zahlen und Fakten der Micarna-Gruppe

Die Micarna-Gruppe beschäftigt an 23 Standorten in der Schweiz rund 3052 Mitarbeitende.

| Mitarbeitende | 3'052 |

| Lernende | 95 |

| Standorte | 23 |

| Produkte | ca. 4'500 |

| Absatz | 170'294 t |

| Frauenanteil | 27.9% |

Zahlen von 2022

News aus der Micarna-Gruppe

Hans-Ruedi Christen übernimmt die Leitung der Micarna-Gruppe

Hans-Ruedi Christen, aktueller CEO der Fresh Food & Beverage Group übernimmt ab 2. Mai 2024 die Führung der Micarna-Gruppe…

Aussergewöhnlichen Berufsweg mit Eidg. Fachausweis gekrönt

Celso Fernandes hat vor Kurzem erfolgreich sein Diplom zum Betriebsleiter Fleischwirtschaft mit Eidg. Fachausweis abgeschlossen…

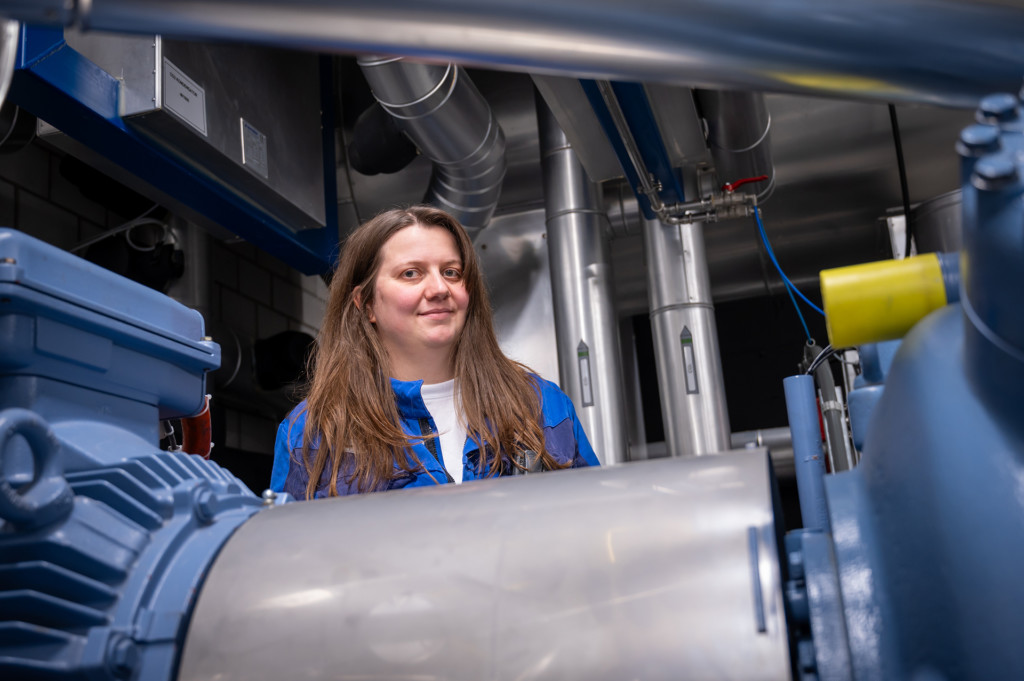

Im Strom der Veränderung

Mit 36 Jahren eine neue Ausbildung zu beginnen erfordert Mut, Entschlossenheit und den Wunsch nach einer Veränderung. Eine…